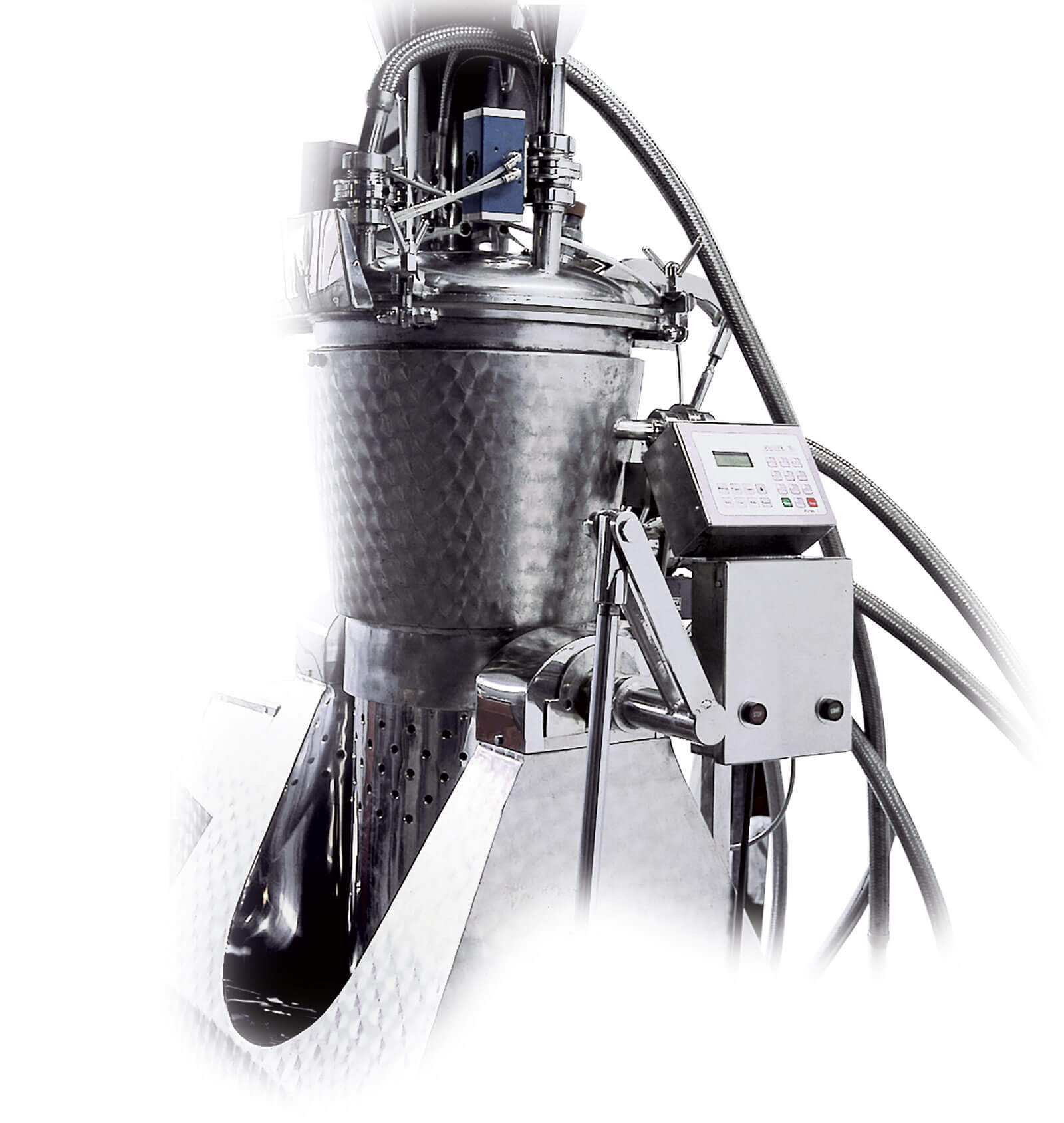

Universal machines “UM” – Cutter

Description:

With this, your product is completely protected from pollution, has high quality and longer shelf life. According to your needs, versions and models from the smallest machines (5 l), intended for laboratory purposes or smaller production, to industrial facilities (500 l) are available. Practically, the possibilities are unlimited – heating, cooling, pasteurization, sterilization, cutting (shredding up to 18 mm), mixing, homogenization, emulsification. UM 200, in line with cistern – raw material tank, with flexible connections. Depending on the needs, it is used to make marmalade, ketchup, mayonnaise, Eurocrem, fruit concentrates, all kinds of melted cheeses, and other pasty products. The process in the appliance lasts 6-10 minutes, followed by the discharge through a special outlet, and the next charge comes from the tank with a volume of 3 volumes on the machine.

Adding any substance during the process is done through dosing machines. If UM is not connected to the packaging line, acceptance of the finished product is done in specially made containers – carts. UM 60 has the same functions as UM 200 and can be used separately and in line. The discharge is mechanical, through built-in pneumatic equipment, and both the lid and the container have a mechanical lock to prevent overturning and possible shocks.